Used Presses and Printing Equipment Inventory – Delivery and Installation is available. Located at the Port of Skagit, in Burlington, WA, imPRESSions Worldwide, Inc. owns all the equipment listed!

Below is a sample of our used press inventory. Since our inventory list changes rapidly, we invite you to contact us if you don’t see what you are looking for. We may very well have it available!

Featured Inventory

https://impressionsworldwide.com/wp-content/uploads/Burnaby-Vanpress-Printers-March-29-2024-14.jpg

665

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-04-09 13:40:132024-04-09 13:40:132005/2007 22.75" Goss SSC Community Press

https://impressionsworldwide.com/wp-content/uploads/Burnaby-Vanpress-Printers-March-29-2024-14.jpg

665

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-04-09 13:40:132024-04-09 13:40:132005/2007 22.75" Goss SSC Community Press https://impressionsworldwide.com/wp-content/uploads/Norway-22inch-Tensor-Press-November-22-2023-1.jpg

768

968

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-12-04 10:58:032024-02-23 11:34:54Automated 22" Tensor Press

https://impressionsworldwide.com/wp-content/uploads/Norway-22inch-Tensor-Press-November-22-2023-1.jpg

768

968

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-12-04 10:58:032024-02-23 11:34:54Automated 22" Tensor Press https://impressionsworldwide.com/wp-content/uploads/6-Anniston-DGM850-Plant-Assets-May-13-2023.jpg

768

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-05-24 12:12:192024-02-23 11:36:532006 Automated DGM 850 Press

https://impressionsworldwide.com/wp-content/uploads/6-Anniston-DGM850-Plant-Assets-May-13-2023.jpg

768

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-05-24 12:12:192024-02-23 11:36:532006 Automated DGM 850 Press https://impressionsworldwide.com/wp-content/uploads/Villages-May-2-2023-5.jpg

723

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-05-04 12:42:062023-11-07 10:45:07DGM 440 Press 22-3/4" Cut-Off, 36" Wide

https://impressionsworldwide.com/wp-content/uploads/Villages-May-2-2023-5.jpg

723

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-05-04 12:42:062023-11-07 10:45:07DGM 440 Press 22-3/4" Cut-Off, 36" Wide https://impressionsworldwide.com/wp-content/uploads/Denmark-560-SSC-February-2023-27.jpg

768

1021

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-03-01 14:36:252023-09-08 08:40:59(2005) GOSS Community Press in Burlington WA

https://impressionsworldwide.com/wp-content/uploads/Denmark-560-SSC-February-2023-27.jpg

768

1021

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-03-01 14:36:252023-09-08 08:40:59(2005) GOSS Community Press in Burlington WACurrent Inventory

https://impressionsworldwide.com/wp-content/uploads/Lake-Charles-clamp-truck-April-2024-1-FP.jpg

768

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-04-15 15:33:492024-04-15 15:33:49E80Z Hyster 8,000 lb. Electric Clamp Truck

https://impressionsworldwide.com/wp-content/uploads/Lake-Charles-clamp-truck-April-2024-1-FP.jpg

768

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-04-15 15:33:492024-04-15 15:33:49E80Z Hyster 8,000 lb. Electric Clamp Truck https://impressionsworldwide.com/wp-content/uploads/Sedalia-SU-Folder-April-2024-3-FP.jpg

784

768

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-04-15 14:26:062024-04-15 14:26:06Goss Suburban Urbanite Folder

https://impressionsworldwide.com/wp-content/uploads/Sedalia-SU-Folder-April-2024-3-FP.jpg

784

768

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-04-15 14:26:062024-04-15 14:26:06Goss Suburban Urbanite Folder https://impressionsworldwide.com/wp-content/uploads/Lake-Charles-STC-70-Gammerler-Stackers-April-2024-10.jpg

679

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-04-15 14:21:072024-04-15 14:21:07Two Gammerler STC 70 Stackers

https://impressionsworldwide.com/wp-content/uploads/Lake-Charles-STC-70-Gammerler-Stackers-April-2024-10.jpg

679

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-04-15 14:21:072024-04-15 14:21:07Two Gammerler STC 70 Stackers https://impressionsworldwide.com/wp-content/uploads/Duluth-Chosun-SSC-Folder-April-2024-16-FP-rotated.jpg

1024

768

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-04-15 14:13:102024-04-15 14:14:072005 Goss SSC Folder

https://impressionsworldwide.com/wp-content/uploads/Duluth-Chosun-SSC-Folder-April-2024-16-FP-rotated.jpg

1024

768

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-04-15 14:13:102024-04-15 14:14:072005 Goss SSC Folder https://impressionsworldwide.com/wp-content/uploads/Burlington_-WA-Goss-magnum-Ink-Keys-January-17_2023.jpg

1600

1200

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

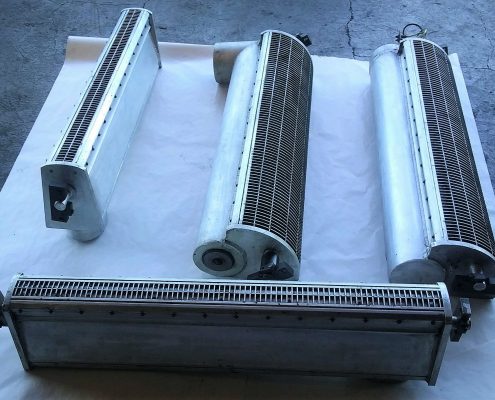

Lindsay Butler2024-02-27 13:17:492024-03-05 16:06:29Goss Magnum Ink Keys

https://impressionsworldwide.com/wp-content/uploads/Burlington_-WA-Goss-magnum-Ink-Keys-January-17_2023.jpg

1600

1200

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-02-27 13:17:492024-03-05 16:06:29Goss Magnum Ink Keys https://impressionsworldwide.com/wp-content/uploads/95-Anniston-DGM850-Plant-Assets-May-13-2023-1.jpg

612

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-02-06 06:33:122024-02-06 06:33:12Jardis Pasters

https://impressionsworldwide.com/wp-content/uploads/95-Anniston-DGM850-Plant-Assets-May-13-2023-1.jpg

612

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-02-06 06:33:122024-02-06 06:33:12Jardis Pasters https://impressionsworldwide.com/wp-content/uploads/Shepherdsville-DGM-1035-Folder-January-2024-7.jpg

1717

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-01-17 07:26:152024-01-17 07:27:4522.75" DGM 1035 Folder

https://impressionsworldwide.com/wp-content/uploads/Shepherdsville-DGM-1035-Folder-January-2024-7.jpg

1717

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2024-01-17 07:26:152024-01-17 07:27:4522.75" DGM 1035 Folder https://impressionsworldwide.com/wp-content/uploads/Vancouver-Kodiak-September-2023-14.jpg

728

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

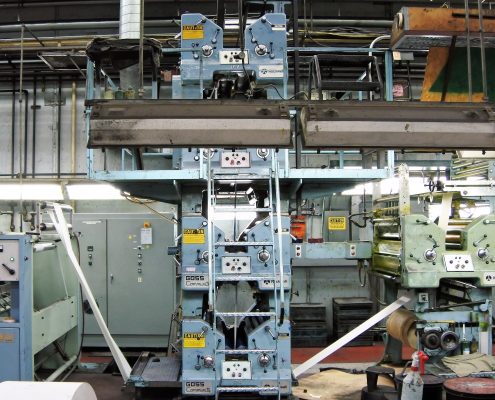

Lindsay Butler2023-09-12 10:13:532024-04-09 13:17:14Goss SSC 21.5” Cut-off Press in Vancouver, BC

https://impressionsworldwide.com/wp-content/uploads/Vancouver-Kodiak-September-2023-14.jpg

728

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-12 10:13:532024-04-09 13:17:14Goss SSC 21.5” Cut-off Press in Vancouver, BC https://impressionsworldwide.com/wp-content/uploads/Burlington-Burgess-Ind.-Plate-Bender-iW-tag-8042-August-31-2023-7.jpg

768

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-07 15:05:312023-09-20 12:27:02Semi-Automatic Plate Bender

https://impressionsworldwide.com/wp-content/uploads/Burlington-Burgess-Ind.-Plate-Bender-iW-tag-8042-August-31-2023-7.jpg

768

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-07 15:05:312023-09-20 12:27:02Semi-Automatic Plate Bender https://impressionsworldwide.com/wp-content/uploads/Burlington-Bugess-Ind.-Plate-Bender-iW-tag-7153-August-31-2023-8.jpg

768

576

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-07 14:02:012023-09-20 12:29:26Semi-Automatic Plate Bender 22" Cutoff

https://impressionsworldwide.com/wp-content/uploads/Burlington-Bugess-Ind.-Plate-Bender-iW-tag-7153-August-31-2023-8.jpg

768

576

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-07 14:02:012023-09-20 12:29:26Semi-Automatic Plate Bender 22" Cutoff https://impressionsworldwide.com/wp-content/uploads/Burlington-Carlson-Plate-Bender-iW-tag-6766-August-31-2023-3.jpg

768

576

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-07 13:55:452023-09-20 12:30:45Semi-Automatic Plate Bender 22" Cutoff

https://impressionsworldwide.com/wp-content/uploads/Burlington-Carlson-Plate-Bender-iW-tag-6766-August-31-2023-3.jpg

768

576

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-07 13:55:452023-09-20 12:30:45Semi-Automatic Plate Bender 22" Cutoff https://impressionsworldwide.com/wp-content/uploads/Burlington-Carlson-Plate-Bender-iW-tag-6765-August-31-2023-4.jpg

768

576

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-07 13:41:282023-09-20 12:31:59Semi-Automatic Plate Bender 22" Cutoff

https://impressionsworldwide.com/wp-content/uploads/Burlington-Carlson-Plate-Bender-iW-tag-6765-August-31-2023-4.jpg

768

576

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-07 13:41:282023-09-20 12:31:59Semi-Automatic Plate Bender 22" Cutoff https://impressionsworldwide.com/wp-content/uploads/Burlington-AWS-OC-4-Oil-Cooler-August-31-2023.jpg

768

358

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-07 11:21:322023-09-07 11:21:51AWS OC 4-Oil Cooler

https://impressionsworldwide.com/wp-content/uploads/Burlington-AWS-OC-4-Oil-Cooler-August-31-2023.jpg

768

358

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-09-07 11:21:322023-09-07 11:21:51AWS OC 4-Oil Cooler https://impressionsworldwide.com/wp-content/uploads/3M-200A-Package-Sealer-MicroJet-II-July-24-2023-1.jpg

1867

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-07-27 14:49:512023-07-27 14:49:51Package Sealer and MicroJet

https://impressionsworldwide.com/wp-content/uploads/3M-200A-Package-Sealer-MicroJet-II-July-24-2023-1.jpg

1867

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-07-27 14:49:512023-07-27 14:49:51Package Sealer and MicroJet https://impressionsworldwide.com/wp-content/uploads/Hankison-Air-Dryer-HPRP500-460-July-24-2023-3.jpg

1050

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-07-27 13:24:182023-07-27 13:24:18Hankinson Air Dryer

https://impressionsworldwide.com/wp-content/uploads/Hankison-Air-Dryer-HPRP500-460-July-24-2023-3.jpg

1050

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-07-27 13:24:182023-07-27 13:24:18Hankinson Air Dryer https://impressionsworldwide.com/wp-content/uploads/New-Philadelphia-Ebway-Splicers-June-2023-2-002.jpg

1050

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-06-21 10:19:552023-06-21 10:19:55Ebway HS35000 Zero Speed Splicers

https://impressionsworldwide.com/wp-content/uploads/New-Philadelphia-Ebway-Splicers-June-2023-2-002.jpg

1050

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-06-21 10:19:552023-06-21 10:19:55Ebway HS35000 Zero Speed Splicers https://impressionsworldwide.com/wp-content/uploads/Tensor-H-50-Folder-June-13-2023-5.jpg

1273

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-06-13 15:02:472023-06-13 15:02:47578 cut-off Tensor H50 Folder

https://impressionsworldwide.com/wp-content/uploads/Tensor-H-50-Folder-June-13-2023-5.jpg

1273

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-06-13 15:02:472023-06-13 15:02:47578 cut-off Tensor H50 Folder https://impressionsworldwide.com/wp-content/uploads/Sedalia-MO.-Urbanite-photos-April-25-2022-1.jpg

1763

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-03-14 11:55:472023-06-21 08:51:30GOSS Urbanite Press - Tupelo, MS

https://impressionsworldwide.com/wp-content/uploads/Sedalia-MO.-Urbanite-photos-April-25-2022-1.jpg

1763

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-03-14 11:55:472023-06-21 08:51:30GOSS Urbanite Press - Tupelo, MS https://impressionsworldwide.com/wp-content/uploads/QRO-475.jpg

768

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-01-26 12:11:242023-01-26 12:48:36VITS Sheeter QRO# 475

https://impressionsworldwide.com/wp-content/uploads/QRO-475.jpg

768

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-01-26 12:11:242023-01-26 12:48:36VITS Sheeter QRO# 475 https://impressionsworldwide.com/wp-content/uploads/STI-model-209-count-o-veyor-January-2023-1.jpg

733

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-01-17 10:27:012023-01-17 10:29:30STI 209 Count-o-veyer

https://impressionsworldwide.com/wp-content/uploads/STI-model-209-count-o-veyor-January-2023-1.jpg

733

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2023-01-17 10:27:012023-01-17 10:29:30STI 209 Count-o-veyer https://impressionsworldwide.com/wp-content/uploads/128-Gainesville-TX-September-21-2022.jpg

691

940

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-10-05 16:03:192023-12-26 11:07:10Gainesville, Texas

https://impressionsworldwide.com/wp-content/uploads/128-Gainesville-TX-September-21-2022.jpg

691

940

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-10-05 16:03:192023-12-26 11:07:10Gainesville, Texas https://impressionsworldwide.com/wp-content/uploads/Sedalia-February-26-2022-41.jpg

768

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-05-02 13:13:172024-04-19 14:38:56NELA Vision Optical Plate Bender - SALE PENDING

https://impressionsworldwide.com/wp-content/uploads/Sedalia-February-26-2022-41.jpg

768

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-05-02 13:13:172024-04-19 14:38:56NELA Vision Optical Plate Bender - SALE PENDING https://impressionsworldwide.com/wp-content/uploads/9-Santa-Catrina-Videplast-Vpak-April-7-20-Copy.jpg

682

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-04-07 12:25:302023-03-09 10:42:29GOSS Sunday 41" Vpak500 7+2 with EB/UV Cure Litho Web Press

https://impressionsworldwide.com/wp-content/uploads/9-Santa-Catrina-Videplast-Vpak-April-7-20-Copy.jpg

682

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-04-07 12:25:302023-03-09 10:42:29GOSS Sunday 41" Vpak500 7+2 with EB/UV Cure Litho Web Press https://impressionsworldwide.com/wp-content/uploads/Ingersoll-Rand-75HP-February-22022-3.jpg

960

1280

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-02-07 16:27:322023-01-19 10:10:53Ingersoll Rand Compressors

https://impressionsworldwide.com/wp-content/uploads/Ingersoll-Rand-75HP-February-22022-3.jpg

960

1280

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-02-07 16:27:322023-01-19 10:10:53Ingersoll Rand Compressors https://impressionsworldwide.com/wp-content/uploads/Anaheim-Bosch-Rexroth-motors-January-20-2022.jpeg

743

1211

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-01-25 06:29:022023-01-19 10:11:07Bosch Rexroth AC Motors

https://impressionsworldwide.com/wp-content/uploads/Anaheim-Bosch-Rexroth-motors-January-20-2022.jpeg

743

1211

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-01-25 06:29:022023-01-19 10:11:07Bosch Rexroth AC Motors https://impressionsworldwide.com/wp-content/uploads/Anaheim-SCNG-Liquidation-January-22-2022-11.jpg

992

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-01-25 06:25:312023-01-19 10:26:27Air Turns and Cushions

https://impressionsworldwide.com/wp-content/uploads/Anaheim-SCNG-Liquidation-January-22-2022-11.jpg

992

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-01-25 06:25:312023-01-19 10:26:27Air Turns and Cushions https://impressionsworldwide.com/wp-content/uploads/Raleigh-NC-November-62021-3-Spray-Bars-4.jpg

1050

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-01-25 06:09:532023-01-19 10:19:58Spray Bars

https://impressionsworldwide.com/wp-content/uploads/Raleigh-NC-November-62021-3-Spray-Bars-4.jpg

1050

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-01-25 06:09:532023-01-19 10:19:58Spray Bars https://impressionsworldwide.com/wp-content/uploads/ink-water-drives-2-scaled.jpg

1781

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-01-18 06:23:402023-01-19 10:20:15Ink and Water Drives - New and Used

https://impressionsworldwide.com/wp-content/uploads/ink-water-drives-2-scaled.jpg

1781

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2022-01-18 06:23:402023-01-19 10:20:15Ink and Water Drives - New and Used https://impressionsworldwide.com/wp-content/uploads/Anaheim-Calibration-Unit-scaled.jpg

1274

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-12-30 12:45:202021-12-30 12:45:20One (1) Baldwin Spray Bar Calibration Unit

https://impressionsworldwide.com/wp-content/uploads/Anaheim-Calibration-Unit-scaled.jpg

1274

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-12-30 12:45:202021-12-30 12:45:20One (1) Baldwin Spray Bar Calibration Unit https://impressionsworldwide.com/wp-content/uploads/Perretta-remote-inking.jpg

683

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-12-28 12:02:092023-06-14 09:05:05Perretta Automation System

https://impressionsworldwide.com/wp-content/uploads/Perretta-remote-inking.jpg

683

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-12-28 12:02:092023-06-14 09:05:05Perretta Automation System https://impressionsworldwide.com/wp-content/uploads/Urbanite-water-motors-Burlington-WA-December-272021-1.jpg

1050

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-12-28 12:01:372023-01-19 10:20:59Urbanite Water Motors

https://impressionsworldwide.com/wp-content/uploads/Urbanite-water-motors-Burlington-WA-December-272021-1.jpg

1050

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-12-28 12:01:372023-01-19 10:20:59Urbanite Water Motors https://impressionsworldwide.com/wp-content/uploads/Orange-Tx.-Brush-Motor.-1-scaled.jpg

2499

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-12-28 12:01:052023-01-19 10:21:23Spiral Brush Motors

https://impressionsworldwide.com/wp-content/uploads/Orange-Tx.-Brush-Motor.-1-scaled.jpg

2499

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-12-28 12:01:052023-01-19 10:21:23Spiral Brush Motors https://impressionsworldwide.com/wp-content/uploads/Raleigh-water-system-2-scaled.jpg

533

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-11-29 09:34:492023-01-19 10:05:29SprayMatic Water System

https://impressionsworldwide.com/wp-content/uploads/Raleigh-water-system-2-scaled.jpg

533

1400

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-11-29 09:34:492023-01-19 10:05:29SprayMatic Water System

Count-o-Veyors

Baldwin 105, 109 and 209 Count-o-Veyors all in stock now!

Three…

https://impressionsworldwide.com/wp-content/uploads/Raleigh-Nov-30-2015-4.jpg

683

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-11-16 12:32:292023-01-19 10:25:41Shaftless Three-Wide Assemblies

https://impressionsworldwide.com/wp-content/uploads/Raleigh-Nov-30-2015-4.jpg

683

1024

Lindsay Butler

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Lindsay Butler2021-11-16 12:32:292023-01-19 10:25:41Shaftless Three-Wide Assemblies https://impressionsworldwide.com/wp-content/uploads/Tensor_DEV_used_press_controllers_consoles_towers-5-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-10-20 10:17:162021-10-20 10:17:51Enkel Splicers

https://impressionsworldwide.com/wp-content/uploads/Tensor_DEV_used_press_controllers_consoles_towers-5-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-10-20 10:17:162021-10-20 10:17:51Enkel Splicers https://impressionsworldwide.com/wp-content/uploads/Paradise-water-chiller-December-3-2019-2.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-10-20 08:13:532021-10-20 08:33:31Water Chiller

https://impressionsworldwide.com/wp-content/uploads/Paradise-water-chiller-December-3-2019-2.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-10-20 08:13:532021-10-20 08:33:31Water Chiller https://impressionsworldwide.com/wp-content/uploads/12-New-Philadelphia-ContiwebDryer-October-7-2021-scaled.jpg

1050

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-10-15 15:59:252024-04-19 14:45:40Contiweb Ecotherm Hot-air Web Offset Dryer - SALE PENDING

https://impressionsworldwide.com/wp-content/uploads/12-New-Philadelphia-ContiwebDryer-October-7-2021-scaled.jpg

1050

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-10-15 15:59:252024-04-19 14:45:40Contiweb Ecotherm Hot-air Web Offset Dryer - SALE PENDING https://impressionsworldwide.com/wp-content/uploads/Pittsfield-150-HP-Drive-September-2021-3-rotated.jpg

1024

768

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-10-06 10:31:042023-01-19 10:26:46Fincor Drive Cabinets – 150HP

https://impressionsworldwide.com/wp-content/uploads/Pittsfield-150-HP-Drive-September-2021-3-rotated.jpg

1024

768

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-10-06 10:31:042023-01-19 10:26:46Fincor Drive Cabinets – 150HP https://impressionsworldwide.com/wp-content/uploads/VARIER-L850-6.jpg

932

1400

ImPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

ImPRESSions Worldwide2021-09-28 11:47:132023-03-09 10:43:57Varier L 850

https://impressionsworldwide.com/wp-content/uploads/VARIER-L850-6.jpg

932

1400

ImPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

ImPRESSions Worldwide2021-09-28 11:47:132023-03-09 10:43:57Varier L 850 https://impressionsworldwide.com/wp-content/uploads/Feature-52-Orange-DGM-Press-15U-2021-03-18_17-52-1-1030x773-1.jpg

773

1030

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-08-09 12:47:472023-03-09 10:39:0922” Cut-off DGM Press

https://impressionsworldwide.com/wp-content/uploads/Feature-52-Orange-DGM-Press-15U-2021-03-18_17-52-1-1030x773-1.jpg

773

1030

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-08-09 12:47:472023-03-09 10:39:0922” Cut-off DGM Press https://impressionsworldwide.com/wp-content/uploads/Coquitlam-at-iW-November-2021-4.jpg

986

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-07-13 16:11:162023-12-19 11:35:20578 Atlas Press with One (1) Quad-Stack

https://impressionsworldwide.com/wp-content/uploads/Coquitlam-at-iW-November-2021-4.jpg

986

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-07-13 16:11:162023-12-19 11:35:20578 Atlas Press with One (1) Quad-Stack https://impressionsworldwide.com/wp-content/uploads/Z-Duluth-SSC.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-05-28 06:54:262021-08-16 14:15:132012 Goss Community SSC Press in 21.5” cut-off

https://impressionsworldwide.com/wp-content/uploads/Z-Duluth-SSC.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-05-28 06:54:262021-08-16 14:15:132012 Goss Community SSC Press in 21.5” cut-off

Belleville Press Equipment

(4) DGM 850 units, (1) 2000 vintage DGM 1030 folder, (1) U-1385 Urbanite folder, Jardis three wide assembly.

https://impressionsworldwide.com/wp-content/uploads/Z-23-Sagebrush-2005-Sunday2000-16-8U2W-22.25-PCF1.1-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-05-20 16:23:332021-08-16 14:14:17(2005) Sunday2000 Press

https://impressionsworldwide.com/wp-content/uploads/Z-23-Sagebrush-2005-Sunday2000-16-8U2W-22.25-PCF1.1-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-05-20 16:23:332021-08-16 14:14:17(2005) Sunday2000 Press

Goss Community SSC Press

These are factory towers, not conversions.

https://impressionsworldwide.com/wp-content/uploads/Feature-goss_community_ssc_press_used_8unit-12.jpg

725

968

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-05-19 13:41:342021-09-09 09:15:10Goss Community SSC Press - 22-3/4” (578) Cut-off

https://impressionsworldwide.com/wp-content/uploads/Feature-goss_community_ssc_press_used_8unit-12.jpg

725

968

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-05-19 13:41:342021-09-09 09:15:10Goss Community SSC Press - 22-3/4” (578) Cut-off https://impressionsworldwide.com/wp-content/uploads/Z-Sweden-Magnum-Used-Press-Equipment-overview-May-30-2020-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

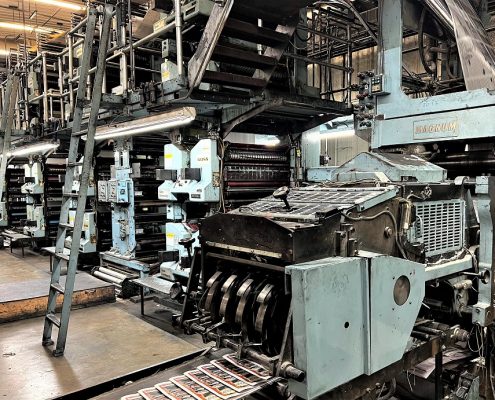

Annette Pankey2021-05-13 08:35:562021-08-16 14:16:25Exceptional Goss Magnum Press

https://impressionsworldwide.com/wp-content/uploads/Z-Sweden-Magnum-Used-Press-Equipment-overview-May-30-2020-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-05-13 08:35:562021-08-16 14:16:25Exceptional Goss Magnum Press

Four Tower WebPress Quad-Stack Press

Available for Sale Exclusively by imPRESSions Worldwide!

SPARE MOTORS

Motors Always Available!

https://impressionsworldwide.com/wp-content/uploads/17-Orange-DGM-Press-15U-2021-03-18_17-52-1.jpg

2048

1536

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-05-04 14:05:032021-08-10 10:34:33DGM 1035 Folder with upper former

https://impressionsworldwide.com/wp-content/uploads/17-Orange-DGM-Press-15U-2021-03-18_17-52-1.jpg

2048

1536

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-05-04 14:05:032021-08-10 10:34:33DGM 1035 Folder with upper former

DGM 1030 Folder

New in 1998. In very good condition. Loaded with features!

DGM 1050 Folder - 22 inch Cut-Off

New 2000 and in excellent condition. Built in Pennsylvania, USA

DGM 1030 Folder with Quarter Folder and Collect

Available Now!

https://impressionsworldwide.com/wp-content/uploads/DGM_1030_Folder_22_cut-off_Used_Press_Equipment-30.jpg

2297

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-30 15:46:522021-06-09 08:41:4422” DGM 1030 Folder for sale!

https://impressionsworldwide.com/wp-content/uploads/DGM_1030_Folder_22_cut-off_Used_Press_Equipment-30.jpg

2297

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-30 15:46:522021-06-09 08:41:4422” DGM 1030 Folder for sale! https://impressionsworldwide.com/wp-content/uploads/560mm_Goss_SSC_Folder_Used_Press_Equipment-1.jpg

1936

1296

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-29 13:53:002021-06-09 08:40:52560 (22”) Goss SSC Folder

https://impressionsworldwide.com/wp-content/uploads/560mm_Goss_SSC_Folder_Used_Press_Equipment-1.jpg

1936

1296

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-29 13:53:002021-06-09 08:40:52560 (22”) Goss SSC Folder https://impressionsworldwide.com/wp-content/uploads/S-Goss_SC_Folder_half_quarter_usedpress-9.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-04-29 08:19:212021-08-16 15:20:18SC Folder #451

https://impressionsworldwide.com/wp-content/uploads/S-Goss_SC_Folder_half_quarter_usedpress-9.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-04-29 08:19:212021-08-16 15:20:18SC Folder #451 https://impressionsworldwide.com/wp-content/uploads/S-Prince-Edward-SSC-Folder-483-6.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-26 07:50:472021-08-16 14:25:37SSC 483 Folder

https://impressionsworldwide.com/wp-content/uploads/S-Prince-Edward-SSC-Folder-483-6.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-26 07:50:472021-08-16 14:25:37SSC 483 Folder https://impressionsworldwide.com/wp-content/uploads/2015-Magnum-N40-Folder-August-2015.jpg

893

684

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-24 12:21:222021-06-09 08:37:43Goss N40 Folder - MSC 9014

https://impressionsworldwide.com/wp-content/uploads/2015-Magnum-N40-Folder-August-2015.jpg

893

684

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-24 12:21:222021-06-09 08:37:43Goss N40 Folder - MSC 9014 https://impressionsworldwide.com/wp-content/uploads/Ink_Pumps_Water_Systems-4-scaled.jpg

924

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-22 10:05:052021-06-09 12:22:38INK PUMPS

https://impressionsworldwide.com/wp-content/uploads/Ink_Pumps_Water_Systems-4-scaled.jpg

924

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-22 10:05:052021-06-09 12:22:38INK PUMPS https://impressionsworldwide.com/wp-content/uploads/Coos-Bay-4-High-March-2021-2-scaled.jpg

2556

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-22 09:59:562021-06-09 08:53:45Factory Correct Goss Community SSC Tower

https://impressionsworldwide.com/wp-content/uploads/Coos-Bay-4-High-March-2021-2-scaled.jpg

2556

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-22 09:59:562021-06-09 08:53:45Factory Correct Goss Community SSC Tower

Factory Goss Urbanite 4-High Towers

Three factory correct Goss Urbanite U-1471 towers

https://impressionsworldwide.com/wp-content/uploads/Goss_community_SSC_tower-1.jpg

1516

1400

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-04-14 10:57:372021-06-09 09:04:55Goss Community 578 cut-off SSC 4 High

https://impressionsworldwide.com/wp-content/uploads/Goss_community_SSC_tower-1.jpg

1516

1400

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-04-14 10:57:372021-06-09 09:04:55Goss Community 578 cut-off SSC 4 High https://impressionsworldwide.com/wp-content/uploads/Goss-SSC-Four-High-1.jpg

1024

628

ImPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

ImPRESSions Worldwide2021-04-09 13:05:022021-06-09 09:07:58Goss SSC Four High From Italy

https://impressionsworldwide.com/wp-content/uploads/Goss-SSC-Four-High-1.jpg

1024

628

ImPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

ImPRESSions Worldwide2021-04-09 13:05:022021-06-09 09:07:58Goss SSC Four High From Italy

Goss Urbanite Units

Floor and stacked unit with lever style ink fountains. These 1000-1300 series Goss Urbanite units are available now at our headquarters!

JARDIS INFEEDS

In Stock Now!

https://impressionsworldwide.com/wp-content/uploads/Duluth-iW-2-web-Slitter-realigner-September-29-2021-5-scaled.jpg

1284

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-03 08:54:162021-10-05 10:37:20Two (2) RP-136 Web Assemblies

https://impressionsworldwide.com/wp-content/uploads/Duluth-iW-2-web-Slitter-realigner-September-29-2021-5-scaled.jpg

1284

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-04-03 08:54:162021-10-05 10:37:20Two (2) RP-136 Web Assemblies

Megtec Splicers

2005 machines ready to go now!

https://impressionsworldwide.com/wp-content/uploads/Sagebrush-January-17-2021-34.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-28 15:12:052021-06-09 09:15:13Eight (8) 2006 Megtec Zero Speed Splicers

https://impressionsworldwide.com/wp-content/uploads/Sagebrush-January-17-2021-34.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-28 15:12:052021-06-09 09:15:13Eight (8) 2006 Megtec Zero Speed Splicers https://impressionsworldwide.com/wp-content/uploads/Jardis_Splicers_Angle_Bars_Infeed_Halifax-8.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-27 12:20:062021-06-17 07:44:43Jardis HS Zero Speed Splicers

https://impressionsworldwide.com/wp-content/uploads/Jardis_Splicers_Angle_Bars_Infeed_Halifax-8.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-27 12:20:062021-06-17 07:44:43Jardis HS Zero Speed Splicers

ASSORTED COMPRESSORS

In Stock Now!!

Email us for a quote!!

Email us for a quote!!

Prime UV Systems

Three Available!

Complete and operating Prime UV systems.

AC Drive System - 150HP

150 HP motor and ABB controller available now in our inventory.

https://impressionsworldwide.com/wp-content/uploads/Fincor_Digital_Press_Drive_Used_Press_Equipment_3.jpg

933

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-19 09:22:412021-06-09 11:00:39Fincor Digital Drive

https://impressionsworldwide.com/wp-content/uploads/Fincor_Digital_Press_Drive_Used_Press_Equipment_3.jpg

933

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-19 09:22:412021-06-09 11:00:39Fincor Digital Drive https://impressionsworldwide.com/wp-content/uploads/Ingersoll_Rand_Screw_Compressor_50_HP-1-e1576523315241.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-16 15:03:232021-10-06 10:05:36Ingersoll Rand Screw Compressor 50 HP

https://impressionsworldwide.com/wp-content/uploads/Ingersoll_Rand_Screw_Compressor_50_HP-1-e1576523315241.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-16 15:03:232021-10-06 10:05:36Ingersoll Rand Screw Compressor 50 HP https://impressionsworldwide.com/wp-content/uploads/Spray-Bars-for-Goss-Community-5.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-14 13:17:262021-06-09 09:42:46Spray Bars for Goss Community in Stock!

https://impressionsworldwide.com/wp-content/uploads/Spray-Bars-for-Goss-Community-5.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-14 13:17:262021-06-09 09:42:46Spray Bars for Goss Community in Stock! https://impressionsworldwide.com/wp-content/uploads/3-Red-Wing-Baldwin-105-2021-07-24_16-05.jpg

1473

1708

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-12 15:12:282021-09-24 10:41:00Three (3) Baldwin Count-o-veyors

https://impressionsworldwide.com/wp-content/uploads/3-Red-Wing-Baldwin-105-2021-07-24_16-05.jpg

1473

1708

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-12 15:12:282021-09-24 10:41:00Three (3) Baldwin Count-o-veyors https://impressionsworldwide.com/wp-content/uploads/Motorized_Conveyor_Used_Press_Equipment-7.jpg

933

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-07 12:51:212021-06-09 11:14:59Motorized Conveyor

https://impressionsworldwide.com/wp-content/uploads/Motorized_Conveyor_Used_Press_Equipment-7.jpg

933

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-03-07 12:51:212021-06-09 11:14:59Motorized Conveyor https://impressionsworldwide.com/wp-content/uploads/Marin_countoveyor_used_press-6.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-03-06 14:38:282021-06-09 11:14:25Baldwin 105 Countoveyor

https://impressionsworldwide.com/wp-content/uploads/Marin_countoveyor_used_press-6.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-03-06 14:38:282021-06-09 11:14:25Baldwin 105 Countoveyor

22-3/4″ Tolerans Stitcher

Excellent condition! Ran only 24,000 copies per week at slow speeds since new in 2005.

https://impressionsworldwide.com/wp-content/uploads/Roll_Clamp_45_Used_Press_Equipment-1-1.jpg

1505

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-02-01 13:43:532021-06-09 12:31:20Roll Clamp

https://impressionsworldwide.com/wp-content/uploads/Roll_Clamp_45_Used_Press_Equipment-1-1.jpg

1505

1400

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-02-01 13:43:532021-06-09 12:31:20Roll Clamp https://impressionsworldwide.com/wp-content/uploads/quincy_100HP_compressor-4-1.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-02-01 08:47:162021-09-24 10:35:00Quincy 100 HP Compressor

https://impressionsworldwide.com/wp-content/uploads/quincy_100HP_compressor-4-1.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-02-01 08:47:162021-09-24 10:35:00Quincy 100 HP Compressor https://impressionsworldwide.com/wp-content/uploads/1-Duluth-SLS2000-1030x691-1.jpeg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-02-01 08:28:292021-09-24 10:29:20Two (2) SLS2000 Inserters available now!

https://impressionsworldwide.com/wp-content/uploads/1-Duluth-SLS2000-1030x691-1.jpeg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-02-01 08:28:292021-09-24 10:29:20Two (2) SLS2000 Inserters available now! https://impressionsworldwide.com/wp-content/uploads/crown_stand_up_forklift_used_press-2-2.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-01-31 14:14:082021-10-12 15:07:39Crown Stand Up Forklift

https://impressionsworldwide.com/wp-content/uploads/crown_stand_up_forklift_used_press-2-2.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-01-31 14:14:082021-10-12 15:07:39Crown Stand Up Forklift https://impressionsworldwide.com/wp-content/uploads/Z-Denmark-Tensor-March-2021-49-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-30 16:50:502021-08-16 14:26:31Tensor T1400 Pressline

https://impressionsworldwide.com/wp-content/uploads/Z-Denmark-Tensor-March-2021-49-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-30 16:50:502021-08-16 14:26:31Tensor T1400 Pressline https://impressionsworldwide.com/wp-content/uploads/Z-Ripon-existing-Press-February-5-2021-13-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-29 12:16:112021-08-16 14:27:11Two (2) Sets of Butler Tandem Splicers

https://impressionsworldwide.com/wp-content/uploads/Z-Ripon-existing-Press-February-5-2021-13-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-29 12:16:112021-08-16 14:27:11Two (2) Sets of Butler Tandem Splicers https://impressionsworldwide.com/wp-content/uploads/Z-PEI_Goss_Community_Used_Press_Equipment-45.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-17 16:39:312021-08-16 14:27:47Goss Community 22-3/4" cut-off with (2) SSC Folders in Prince Edward Island

https://impressionsworldwide.com/wp-content/uploads/Z-PEI_Goss_Community_Used_Press_Equipment-45.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-17 16:39:312021-08-16 14:27:47Goss Community 22-3/4" cut-off with (2) SSC Folders in Prince Edward Island https://impressionsworldwide.com/wp-content/uploads/Z-Heidelberg-V30-feature.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-17 14:07:532021-08-16 14:29:28Heidelberg V30 Press with JF25C Folder!

https://impressionsworldwide.com/wp-content/uploads/Z-Heidelberg-V30-feature.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-17 14:07:532021-08-16 14:29:28Heidelberg V30 Press with JF25C Folder! https://impressionsworldwide.com/wp-content/uploads/Z-Quad-Stack-with-Remote-Inking-RS.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-17 11:18:232021-08-16 14:30:10One owner 2004 Quad-Stack Press with Remote Inking!

https://impressionsworldwide.com/wp-content/uploads/Z-Quad-Stack-with-Remote-Inking-RS.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-17 11:18:232021-08-16 14:30:10One owner 2004 Quad-Stack Press with Remote Inking! https://impressionsworldwide.com/wp-content/uploads/Z-SOP-Heidelberg-Mercury-used-press-equipment-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-16 15:08:042021-08-16 15:28:0212 Tower Heidelberg Mercury Press

https://impressionsworldwide.com/wp-content/uploads/Z-SOP-Heidelberg-Mercury-used-press-equipment-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-16 15:08:042021-08-16 15:28:0212 Tower Heidelberg Mercury Press https://impressionsworldwide.com/wp-content/uploads/Z-Obun_Komori_L426_Used_Press_Equipment-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-15 12:01:532021-08-16 15:29:54Four Unit Komori L426 Sheetfed Press

https://impressionsworldwide.com/wp-content/uploads/Z-Obun_Komori_L426_Used_Press_Equipment-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-15 12:01:532021-08-16 15:29:54Four Unit Komori L426 Sheetfed Press https://impressionsworldwide.com/wp-content/uploads/Z-Pacific-Northwest-M-600-January-2019-1.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-01-14 11:16:052021-08-16 14:41:12HEIDELBERG M600 B24 Press System

https://impressionsworldwide.com/wp-content/uploads/Z-Pacific-Northwest-M-600-January-2019-1.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-01-14 11:16:052021-08-16 14:41:12HEIDELBERG M600 B24 Press System https://impressionsworldwide.com/wp-content/uploads/Z-1-Las-Vegas-Creel-855-Saddle-Stitcher-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-13 13:23:162021-08-16 14:42:25HARRIS 855 Full Format Saddle Stitcher

https://impressionsworldwide.com/wp-content/uploads/Z-1-Las-Vegas-Creel-855-Saddle-Stitcher-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-13 13:23:162021-08-16 14:42:25HARRIS 855 Full Format Saddle Stitcher https://impressionsworldwide.com/wp-content/uploads/Z-Sagebrush-Sunday2000-74-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-12 14:52:252021-08-16 14:18:45(2000) Sunday2000 Heidelberg Press

https://impressionsworldwide.com/wp-content/uploads/Z-Sagebrush-Sunday2000-74-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-12 14:52:252021-08-16 14:18:45(2000) Sunday2000 Heidelberg Press https://impressionsworldwide.com/wp-content/uploads/Z-IMG_2131.jpeg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-12 12:55:102021-08-16 14:44:34Gammerler KL 6000 Stackers

https://impressionsworldwide.com/wp-content/uploads/Z-IMG_2131.jpeg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-12 12:55:102021-08-16 14:44:34Gammerler KL 6000 Stackers https://impressionsworldwide.com/wp-content/uploads/Z-2004-Goss-Commuity-SSC-Four-High-with-Jardis-Splicer-3.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-11 16:00:372021-08-16 14:21:542004 Goss Community SSC Four High

https://impressionsworldwide.com/wp-content/uploads/Z-2004-Goss-Commuity-SSC-Four-High-with-Jardis-Splicer-3.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-11 16:00:372021-08-16 14:21:542004 Goss Community SSC Four High https://impressionsworldwide.com/wp-content/uploads/Z-ctpIMG_2240.jpeg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-11 15:42:002021-08-16 14:22:4457” Fully Automated CTP, Bender and Stacker/Sorter Line

https://impressionsworldwide.com/wp-content/uploads/Z-ctpIMG_2240.jpeg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-11 15:42:002021-08-16 14:22:4457” Fully Automated CTP, Bender and Stacker/Sorter Line https://impressionsworldwide.com/wp-content/uploads/Z-4-Las-Vegas-Creel-Lantech-Pallet-Wrapper.-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-10 12:48:022021-08-16 14:45:18Lantech Pallet Wrapper

https://impressionsworldwide.com/wp-content/uploads/Z-4-Las-Vegas-Creel-Lantech-Pallet-Wrapper.-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-10 12:48:022021-08-16 14:45:18Lantech Pallet Wrapper https://impressionsworldwide.com/wp-content/uploads/S-yale_clamp_truck_used_press-12.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-01-09 14:04:402021-08-31 14:41:44Yale Clamp Truck

https://impressionsworldwide.com/wp-content/uploads/S-yale_clamp_truck_used_press-12.jpg

683

1024

imPRESSions Worldwide

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

imPRESSions Worldwide2021-01-09 14:04:402021-08-31 14:41:44Yale Clamp Truck https://impressionsworldwide.com/wp-content/uploads/S-PFF-FOlder-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-09 13:06:592021-08-16 14:46:38PFF Folder

https://impressionsworldwide.com/wp-content/uploads/S-PFF-FOlder-scaled-1.jpg

683

1024

Annette Pankey

https://impressionsworldwide.com/wp-content/uploads/impressions-WW-300x96.png

Annette Pankey2021-01-09 13:06:592021-08-16 14:46:38PFF Folder