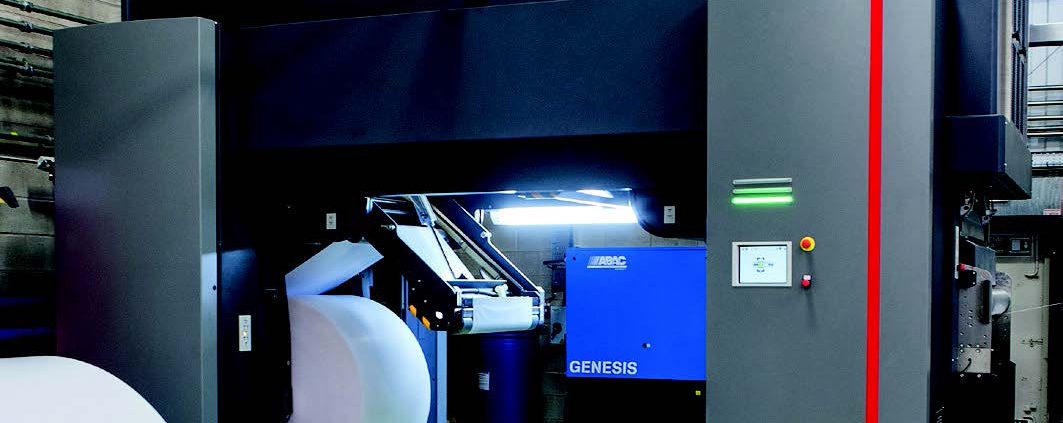

Contiweb Fluid Applicator (CFA)

This system controls individually the oil and water content applied to each side of the web. Two combined functions to enhance print quality and reduce expenses. The function of remoistening prevents growth of cut signatures. The application of pure silicone guarantees a considerable reduction in silicone oil consumption.

Gas Dryer

Ecocool/W dryers are designed for use with a separate afterburner. Hot air is produced in two compact burner units positioned on either side of the web. Partial recirculation of the exhaust air towards the burner chambers means that vaporized solvents from the ink contribute to the air heating process. At the same time, the exhaust air volume is reduced, thus minimizing the capacity and energy requirements of the central afterburner. This design results in reduced gas consumption in the dryer and in the pollution control unit by up to 30 percent.

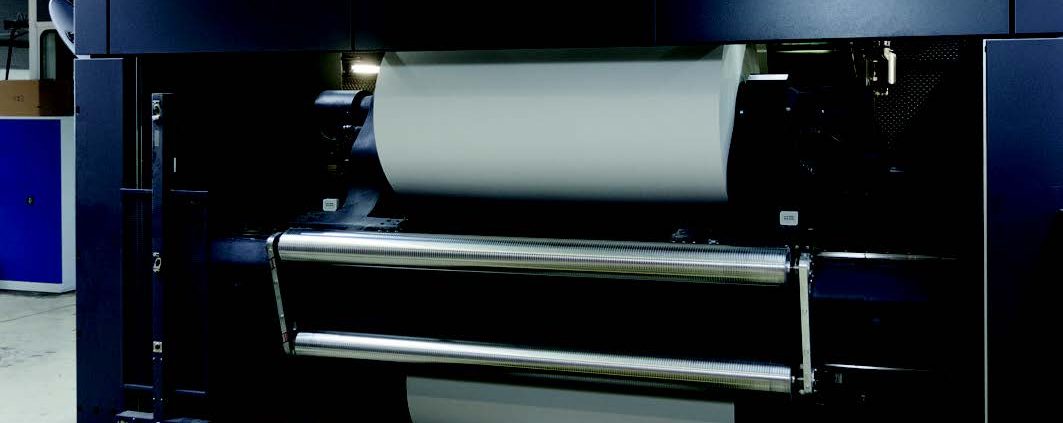

Web offset Zero-speed splicer & Flying paster

From extensive automation to proven reliability and performance features, Contiweb splicing and pasting technology for non-stop unwinding provides real advantages in the pressroom. Those advantages impact productivity, efficiency and profitability. Specifically designed for seamless integration with all press systems. They are also proven, cost effective solutions for press rebuild and enhancement projects.

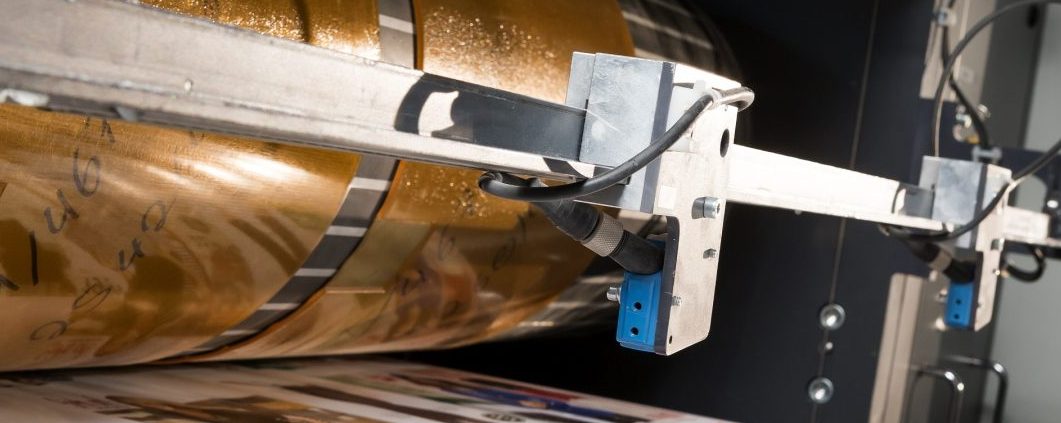

VITS Sheeter

Contiweb Rotocut sheeters are high-speed sheeters that maintain speeds up to 75.000 imp/h resulting in high productivity. The integrated print-to-cut register control ensures that the Rotocut maintains its high speed and high productivity without compromising in accuracy. The application of direct drives enables the highest cutting accuracy (up to +/- 0,2 mm (print-to-cut). Besides its high quality the Contiweb Rotocut operates with a minimal amount of waste when starting the printing press. By adding an automated pallet transport system, a cost-effective workflow is secured

Digital Press Solutions and Services:

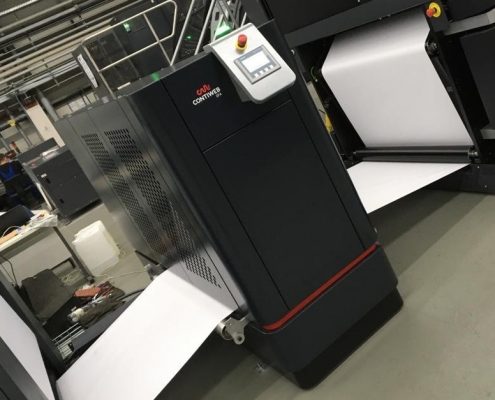

Unwinder and Rewinder

The Contiweb CD series is a modular system of reel splicing solutions designed to cover the full range of the web paper infeed requirements for digital inkjet as well as label and package printing. The models from entry-level unwinders (CD-W) up to fully automatic, high-speed splice (CD-N) feature proven Contiweb precision engineering to ensure accuracy and repeatability at every stage of the process.

Specifically designed for the specialized requirements of the digital, label and package printing market, the Contiweb CR series of modular rewinders consists of two models to cater for entry-level manual rewind capabilities (CR-W) and fully automatic rewinding at full press speed (CR-N). Whatever the level of automation required, the rewinders feature proven Contiweb precision engineering to ensure accuracy and repeatability at every stage of the process.

Digital Fluid Applicator (DFA)

The Contiweb Digital Fluid Applicator (DFA) is a standalone remoistening applicator for digital web presses, that can optionally also apply silicone. This provides companies with greater remoistening control, ensuring that the final product regains moisture and does not distort from absorbing it form the environment.

Inline Finishing

With 2012 acquisition of Jetweb, Contiweb offers high quality inline finishing systems with experience based on over 1,000 systems worldwide; that offer Flexible, modular High-speed production.

Variable Width Coater & Primer for Aqueous based coatings

Specially designed for digital inkjet applications; duplex flood coater for Inline or Offline primer and OPV. No need for sleeves or anilox rollers to accurately apply measurable amounts of coating to each side of the substrate.